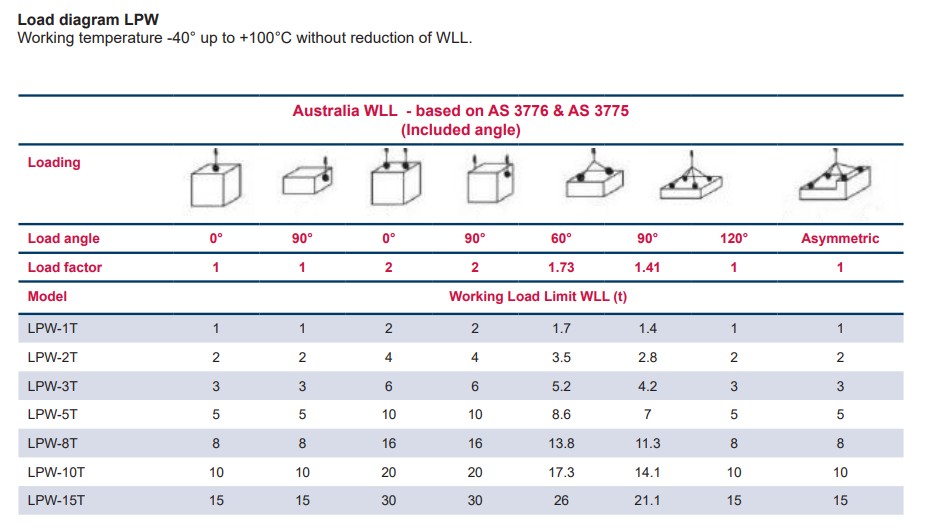

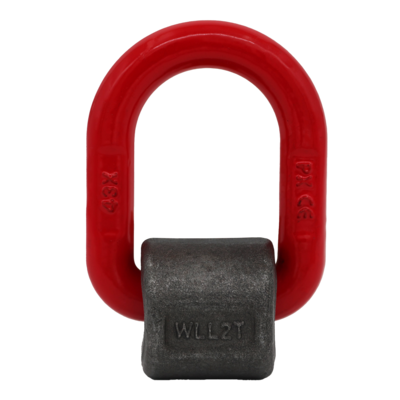

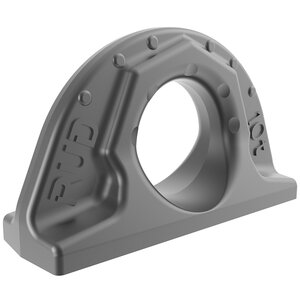

The POWERTEX Lifting Point Weldable - LPW is an indispensable tool primarily utilized for establishing secure lifting points on heavy machinery and equipment such as excavators, earth-moving machines, lifting beams, and various tools. Designed to be permanently attached through welding, the LPW offers a fixed lifting point that allows for a 180-degree pivot, enhancing its versatility in operation. It features a forged housing with an integrated forged D-ring and a spring mechanism that keeps the D-ring snugly against the surface, significantly reducing noise and movement, particularly in high-vibration environments.

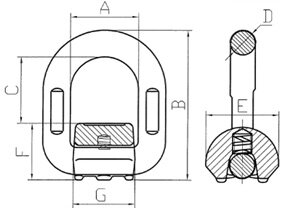

Allowed Loading directions:

- +/- 90° in the pivot plane over the housing

- Same WLL in all directions

- WLL According to WLL Diagram

Product Features:

- Durable finish: Coated in PURE RED powder paint, the Powertex LPW lifting points are visually distinct and offer superior resistance to wear and corrosion.

- Welding preparedness: The housing is specifically blasted to create an optimal surface for welding, ensuring a robust and reliable bond when welded by a certified professional.

- Compliance to standard: Manufactured to meet the testing requirements specified by EN 1677-1, ensuring high safety and quality standards.

- Reliable: Designed with a safety factor of at least 4 in the intended load directions, offering a secure lifting experience.

- Quality assurance: Each component undergoes crack detection testing in the factory and forged links are proof load tested to ensure reliability.

- Type testing: Each model undergoes type testing, including breaking tests and fatigue tests to 20,000 cycles at 1.5 times the WLL in the factory, highlighting the product's endurance.

- Full traceability: Every component is marked with POWERTEX branding, model name, WLL, CE-mark, UKCA-mark, and a traceability code, ensuring traceability to the production lot and raw materials.

- Uniform WLL: The LPW maintains the same WLL in all intended directions, simplifying load planning and increasing versatility.

- Harmless: Chromium 6 free, aligning with environmental safety standards.

- Certificates included: Comes with a POWERTEX 2.2 certificate & Declaration of Conformity with each box, confirming compliance with EC and UK regulations.

- Wide temperature range: Optimized for use between -40°C to +100°C without WLL reduction, with permissible WLL reductions for higher temperature ranges, ensuring adaptability to various environments.

- Features: Weldable, same WLL in all intended load directions (no side-loading)

- Material: Forged Alloy Steel

- Marking: According to standard, CE-marked, UKCA-marked, POWERTEX, model name, WLL and batch number

- Temperature range: -40 up to +100°C without reduction in WLL

- Finish: Powder painted in PURE RED

-

Standard:

EN 1677-1

Australian Standard: AS 3776 - Note: The LPW is WLL (Working Load Limit) rated, assuming that the correct welding procedure is meticulously followed and executed by a suitably qualified welder, to maintain the product's integrity and compliance with safety regulations.