In the world of lifting and rigging, the humble shackle stands as a fundamental component, offering versatility and strength in various applications. However, choosing the right shackle for specific lifting needs requires careful consideration. Our Know How will unravel the intricacies of shackle selection, guiding you toward making informed choices for your lifting requirements.

Understanding Shackles: Types and Variations

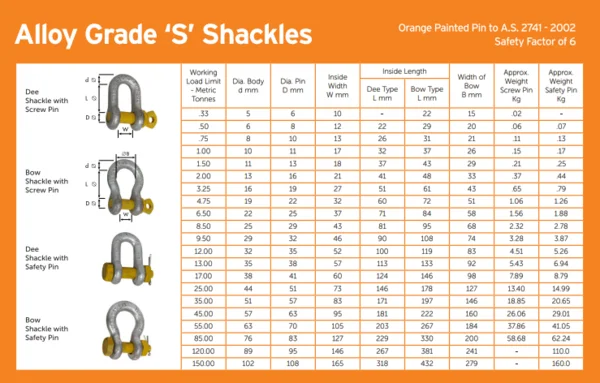

- Bow Shackles vs. Dee Shackles: Bow shackles, with their rounded shape, offer versatility for multi-directional loading, while dee shackles, with their straight-sided design, provide better load alignment.

- Material Varieties: Shackles come in various materials, such as stainless steel, carbon steel, and alloy steel, each offering specific benefits of strength, corrosion resistance, and suitability for different environments.

- Design Considerations: Different designs, including screw pin, bolt type, and safety pin shackles, cater to various applications and provide varying levels of security and ease of use.

Factors Influencing Shackle Selection

- Load Requirements: Consider the load capacity, working load limit (WLL), and the specific forces the shackle will endure. Choose a shackle with a WLL that comfortably exceeds your intended load.

- Environmental Conditions: Factor in the environment where the shackle will be used. Stainless steel might be suitable for corrosive environments, while alloy steel could be preferred for heavy-duty applications.

- Usage Specifications: Assess the intended use, considering factors like angle of loading, frequency of use, and compatibility with other lifting components to ensure seamless integration and efficiency.

Safety Standards and Compliance

- AS/NZS 2741: Lifting Equipment - Part 1: Shackles: Australian and New Zealand standards specify requirements for shackles, ensuring their strength, durability, and safety in lifting operations.

- Certifications and Markings: Look for shackles with markings indicating compliance with standards, certifications, or load ratings, ensuring they meet specified safety criteria.

Making the Right Choice

- Expert Guidance: Consult our lifting and rigging professionals to determine the most suitable shackle for your specific lifting needs. Get in touch to speak with one of our knowledgeable team members.

- Quality and Reliability: Prioritise quality and reliability when selecting shackles, opting for reputable manufacturers or suppliers known for adhering to safety standards.

At CERTEX Lifting, we offer a range of shackles meticulously selected to meet diverse lifting needs while ensuring compliance with Australian standards. Our commitment is to provide equipment and solutions that elevate safety, reliability, and efficiency in your lifting and rigging operations.

Contact us today to explore our comprehensive range of shackles and discover how our expertise can assist in meeting your lifting requirements with precision and safety at the forefront.

Hardware Maintenance

Outlining the importance of maintenance and inspection of lifting hardware.

Swivels and Hooks for Lifting

An exploration of the pivotal roles played by swivels and hooks.