Wire rope slings are indispensable for numerous industries, providing reliable and versatile solutions for lifting, rigging and materials handling operations. These flexible and durable assemblies consist of wire ropes braided together to form a robust structure capable of withstanding heavy loads under challenging conditions. Understanding the technical aspects of wire rope slings ensures they are used safely and efficiently. The design, proof loading, and certification of your wire rope sling depend on the country and application in which you wish to use it. If you are unsure of the requirements, our specialists can guide you on getting the correct information for your enquiry.

Composition

Composition

Wire rope slings are typically made from multiple strands of wire ropes, meticulously braided or twisted together to form a robust and flexible structure. These slings consist of an assembly of wire ropes, incorporating a range of diameters and constructions based on their intended usage and load requirements.

Types and Configurations

Types and Configurations

Steel wire rope slings are available in numerous configurations, including single-leg, double-leg, or multiple-leg designs, each tailored to specific lifting needs. Having variations in the number of legs, eye configurations and end fittings allows for flexibility in securing and lifting diverse loads.

Capacity and Load Ratings

Capacity and Load Ratings

Manufactuerer's provide load ratings and specifications based on the sling's configuration, diameter, material and contstruction type. Each sling has either a marking plate or be marked in the ferrules (single leg and endless slings) with the manufacturer's identifying mark, working load limit (WLL), length, manufacturing date and CE marking.

Applications

Applications

Steel wire rope slings are useful across a wide variety of industries, including construction, maritime, manufacturing and transportation. Their versatile nature makes them highly suitable for a range of lifting and rigging operations, such as crane lifting, materials handling and securing heavy loads.

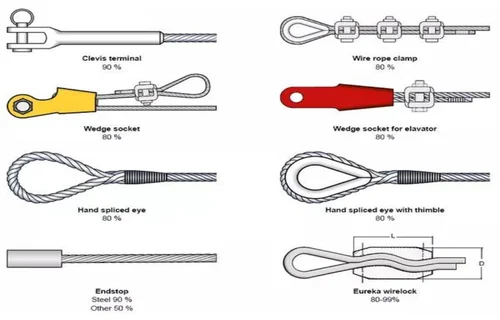

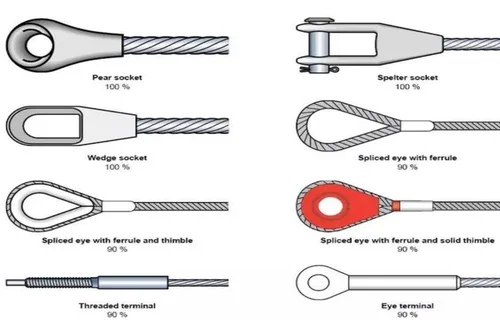

Wire Rope Fittings

Wire Rope Fittings

The most commonly used rope fittings with indication of remaining percentage of steel wire min breaking force.

Steel wire rope slings have proven themselves as a versatile and robust tool capable of numerous lifting and rigging tasks. Understanding their technical specifications and applications empowers users to make informed descisions, ensuring safety, efficiency and longevity in their lifting. For more information about our steel wire rope sling offerings at CERTEX Lifting, contact us below.

Wire Rope Diameter

Understand how wire rope's diameter impacts its strength, flexibility and weight tolerance.

Discarding Steel Wire Rope

How to sustainably and safely discard steel wire rope at the end of its service life.