Wire rope diameter and tolerances play a pivotal role in determining the strength, flexibility and suitability of wire ropes for specific lifting and rigging tasks. These measurements hold significance in various industries, influencing the rope's load bearing capacity, performance and compliance with safety standards. Understanding these factors is crucial for selecting the correct wire rope.

Diameter Measurement

Diameter Measurement

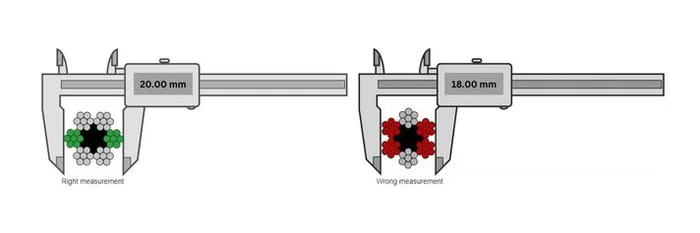

The diameter of a wire rope refers to the measurement across the rope, including the strands and wires. The rope diameter shall always be checked before installation. To do so, measure a minimum of one metre at two sections of a straight part of the rope. At every point two measurements shall be done, with 90 degrees displacement in relation to each other.

Tolerances

Tolerances

Wire rope diameters are manufactured with specific tolerances, indicating the allowable deviation from the nominal or specificed diameter. These tolerances, which vary depending on the rope's construction, material and intended useage, ensure consistency and reliability in rope performance.

Importance of Diameter and Tolerances

Importance of Diameter and Tolerances

The diameter and tolerances of wire ropes are critical factors determining their suitability for various applications. Exact diameter measurements ensure the rope is compatible with certain fittings, sheaves and drums, which allows for smoother operating and avoids damage that may be caused by misalignment or excessive friction. Tolerances also play a crucial role in safety and compliance with industry standards. Ropes manufactured within specificed tolerances adhere to safety regulations, ensuring the rope is reliable and thus minimising risks associated with overloading the rope.

Applications

Applications

Different industries have varying rope diameters and tolerances based on the load requirements. For instance, heavy lifting loads in construction demand ropes with precise diamters and strict adherance to tolerances to ensure safe and reliable lifting operations.

Maintainance

Maintainance

Regular inspections are crucial to ensure rope diameters and adherance to specified tolerances. Regular inspections for wear, corrosion or diameter deviations ensures the rope remains reliable and safe during operations.

Understanding wire rope diameters and tolerances is crucial to determine the correct rope for your task at hand. Adhering to specified tolerances, having regular inspections and complying with safety standards is the key to ensure the reliability, safety and efficiency of wire ropes. If you require further assistance in understanding the world of wire ropes, don't hesitate to contact our knowledgable staff.